Your supply chain is fragile and complex. A single disruption can cause massive losses. The future of multimodal transport offers a smarter, more resilient way to move goods globally.

The future of multimodal transport is being reshaped by five key trends: smart connectivity, green policies, automated hubs, new data standards, and a focus on resilience. These trends work together to create supply chains that are more efficient, sustainable, and robust against disruptions.

These trends are not just abstract ideas for the future. They are real changes happening right now, transforming how we think about logistics. The synergy between new technology and new rules is creating a system that is stronger and smarter than ever before. It’s an evolution from a simple transportation option into a core pillar of modern global trade.

Let's dive into each of these trends to understand how they will impact your business and the entire supply chain ecosystem.

How is Smart Connectivity1 Creating Seamless Integration?

Data silos cause confusion and you lose track of shipments. This leads to costly errors. Technology offers a single source of truth, connecting every step of the journey.

Smart connectivity uses technologies like IoT, AI, and blockchain to link all parts of the transport journey. This provides real-time visibility and predictive insights. It makes the entire process seamless, transparent, and much more efficient for everyone involved.

For years, we've treated each leg of a journey—sea, rail, road—as a separate event. The handover points were black boxes. I remember a time when a client’s container of sensitive electronics was ruined because we couldn't monitor its temperature between the port and the warehouse. That kind of problem is now being solved by technology. Smart connectivity weaves all these separate threads into a single, visible tapestry. It gives us the power to see everything, everywhere, all at once.

The Role of IoT2 and Sensors

Internet of Things (IoT) devices are the eyes and ears of the modern supply chain. We place small sensors on containers, pallets, and even individual products. These sensors constantly report their status. They tell us their exact location, the temperature, humidity levels, and if they have been dropped or opened. This is not just tracking; it is active monitoring. It allows us to prevent problems before they happen. For example, if a refrigerated container's temperature rises, we get an alert immediately, not after the goods have spoiled. This level of control was impossible just a decade ago.

AI3 and Predictive Analytics

All the data from IoT2 sensors is fed into Artificial Intelligence (AI) systems. AI doesn't just show us what is happening now; it predicts what will happen next. It analyzes weather patterns, port congestion, and traffic data to forecast delays. It can then suggest alternative routes to keep shipments on schedule. This moves us from being reactive to being proactive. Instead of just tracking a delay, we can avoid it entirely.

| Old Way (Siloed Data) | New Way (Smart Connectivity) |

|---|---|

| Manual tracking updates | Real-time, automated location data |

| No visibility at handovers | Full visibility across all modes |

| Reacting to problems | Predicting and avoiding problems |

| Estimated arrival times | Accurate, AI-powered ETAs |

How are Green Policies4 Driving a Low-Carbon Transition5 in Transport?

Environmental regulations are getting stricter. Customers demand sustainability. Your company's carbon footprint is under scrutiny, and you need a solution to reduce your environmental impact.

Government policies and consumer pressure are pushing the entire transport industry toward greener operations. Multimodal transport is at the center of this shift, offering more efficient routes and promoting low-carbon fuels. This helps reduce emissions and often cuts long-term operational costs.

The push for sustainability is no longer just about public relations. It has real financial consequences. I've worked with companies that faced heavy fines for not meeting emissions standards. On the other hand, I have seen businesses gain a huge competitive advantage by marketing their green supply chains. Consumers are voting with their wallets, and they are choosing sustainable brands. This means that a low-carbon transition is not just a regulatory burden; it is a business opportunity. Multimodal transport is the most practical way to achieve these green goals.

The Impact of Carbon Taxes6 and Incentives

Governments around the world are implementing policies to make pollution expensive. Carbon taxes add a direct cost to using fossil fuels, forcing companies to find cleaner alternatives. At the same time, they offer incentives like tax breaks or grants for businesses that invest in green technology. This financial push and pull is accelerating the adoption of sustainable practices. It makes a long-haul truck journey less attractive than a more fuel-efficient rail and sea combination. The economics are shifting, and green choices are becoming the smart financial choices.

The Shift to Sustainable Fuels7

This policy-driven change is fueling incredible innovation. We are seeing a rapid shift toward new energy sources across all modes of transport.

- Road: Electric and hydrogen-powered trucks are becoming more common for first and last-mile delivery.

- Sea: Shipping lines are experimenting with low-sulfur fuels, LNG, and even wind-assisted propulsion systems.

- Rail: Electrification of rail lines is a major focus, as it is one of the most energy-efficient ways to move goods over land.

This transition is complex and requires significant investment, but it is essential for the long-term health of our planet and our industry.

How are Automation Hubs8 Revolutionizing Logistics Nodes9?

Port and warehouse operations are slow and labor-intensive. Human error creates delays and safety risks. Automation offers a faster, safer, and more reliable alternative for these critical hubs.

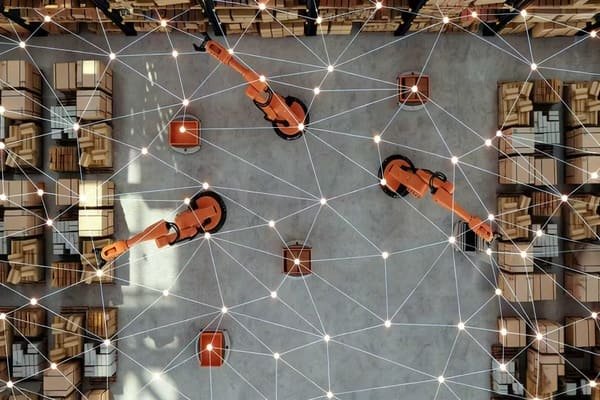

Automated logistics hubs use robots, autonomous vehicles, and smart cranes to handle goods. This technology dramatically speeds up loading, unloading, and sorting. It reduces turnaround times for ships and trucks, minimizes errors, and creates a much safer working environment.

I recently visited an automated port terminal, and it was like watching a science fiction movie. Huge, unmanned cranes moved containers with perfect precision. Fleets of autonomous vehicles transported them to be stacked, all orchestrated by a central AI. There were very few people on the ground. The efficiency was breathtaking. A ship that used to take three days to unload can now be done in less than 24 hours. This isn't just a small improvement; it is a complete revolution in how we handle goods at the most important connection points in the supply chain.

From Manual Labor to Robotic Precision10

The core of an automation hub is the replacement of repetitive manual tasks with machines.

- Automated Guided Vehicles11 (AGVs): These are self-driving vehicles that transport containers and pallets around a port or warehouse.

- Robotic Arms: These can pick, sort, and place packages with speed and accuracy far beyond human capability.

- Automated Storage and Retrieval Systems (AS/RS): These systems use robotic cranes to store and retrieve goods in massive warehouses, optimizing space and speed.

This technology reduces the risk of human error, such as sending a container to the wrong place, and it significantly improves safety by keeping people away from heavy machinery.

The 24/7 Logistics Hub

One of the biggest advantages of automation is that robots don't get tired. An automated hub can operate 24 hours a day, 7 days a week, at maximum capacity. This eliminates the bottlenecks that used to occur during shift changes or holidays. It means that goods are always moving, which is essential for today's fast-paced global economy. This constant flow of cargo makes the entire supply chain more predictable and reliable.

Why are Data Standards and Sovereignty a Double-Edged Sword?

Sharing data is essential for an efficient supply chain. But who owns that data, and how is it protected? These questions create risk, hesitation, and operational friction.

Global data standards are needed for different systems to communicate seamlessly. However, regional data sovereignty laws create challenges by restricting how data can be shared across borders. Finding a balance between open collaboration and secure control is a major challenge for the future.

This is one of the most complex issues we face. On one hand, we need open platforms where a carrier in China can seamlessly share data with a port in Europe and a trucking company in the United States. This is the only way to achieve true end-to-end visibility. On the other hand, countries and companies are rightly concerned about protecting sensitive commercial and personal data. I've been in meetings where progress on a new digital platform stalled completely because lawyers couldn't agree on data ownership and privacy rules. This is the "soft" infrastructure that is just as critical as the "hard" infrastructure of ships and cranes.

The Push for Global Standards

To solve the collaboration problem, industry groups are working to create a common digital language. Organizations like the Digital Container Shipping Association (DCSA) are developing open-source standards for things like track-and-trace data and electronic bills of lading. The goal is to create a "plug-and-play" environment where any company, big or small, can connect its systems to the global network without needing custom integrations. This would dramatically lower the barrier to entry for digital logistics and foster more competition and innovation.

The Reality of Regional Rules

While the industry pushes for global standards, governments are pulling in the other direction with data sovereignty laws. Regulations like the GDPR in Europe place strict rules on how personal data can be processed and transferred. Other countries have similar laws that require certain data to be stored within their borders. This creates a patchwork of different rules that global logistics companies must navigate. It can make a simple data transfer a complex legal issue.

| Pros of Standardization | Challenges of Sovereignty |

|---|---|

| Seamless communication | Data flow restrictions |

| Lower integration costs | Increased compliance costs |

| Increased efficiency and visibility | Risk of data fragmentation |

| Fosters innovation | Creates legal and technical hurdles |

Why is Resilience the New Core Value of Multimodal Transport?

Recent global events showed us how fragile supply chains are. A single point of failure can halt everything. Your business needs a stronger, more adaptable system to survive.

Resilience is now more important than just speed or cost. Multimodal transport builds resilience by providing multiple routes and modes of transport. This flexibility allows supply chains to quickly adapt to disruptions, keeping goods moving when one path is blocked.

For decades, the industry was obsessed with the "just-in-time" model. It was all about minimizing inventory and maximizing speed. Then the pandemic hit, and we saw how quickly that system could break. I had a client whose entire business depended on a single port. When that port closed, their supply chain collapsed. We helped them rebuild using a multimodal strategy, with options for both sea and rail transport through different corridors. The next time a disruption happened, they simply rerouted their cargo and barely missed a beat. That experience taught me that flexibility is the new currency of logistics.

Moving Beyond 'Just-in-Time'

The old focus on pure efficiency created very lean but very brittle supply chains. The new model is about building a "just-in-case" system. This doesn't mean going back to holding massive amounts of expensive inventory. Instead, it means building a supply chain with options. It's about knowing you have a Plan B and a Plan C. This requires better visibility and planning, which ties back to the importance of smart connectivity and data. You need to see the disruption coming and have the information to make a quick decision on how to avoid it.

The Power of Redundancy12 and Flexibility

Multimodal transport is the ultimate tool for building this redundancy. If a major shipping lane is blocked, you can shift more volume to a land bridge using rail. If a key port is congested, you can divert to a smaller port and use trucks for the final leg. This ability to switch between modes and routes is what makes a supply chain truly resilient. It transforms a potential disaster into a manageable problem. This flexibility is no longer a luxury; in today's unpredictable world, it is an absolute necessity for survival and growth.

Conclusion

The future of transport is a blend of smart technology and clear rules. Together, they are building a global supply chain that is efficient, green, automated, and incredibly resilient.

Explore how Smart Connectivity enhances visibility and efficiency in logistics, transforming supply chain operations. ↩

Discover the role of IoT in real-time monitoring and data collection, revolutionizing supply chain management. ↩

Learn how AI predicts delays and optimizes routes, making supply chains more proactive and efficient. ↩

Understand how Green Policies are shaping sustainable transport practices and reducing carbon footprints. ↩

Find out strategies for transitioning to low-carbon operations and the benefits of sustainable logistics. ↩

Discover how carbon taxes are driving companies towards greener logistics solutions. ↩

Learn about innovations in sustainable fuels and their impact on reducing emissions in logistics. ↩

Explore how Automation Hubs enhance efficiency and safety in logistics operations through advanced technology. ↩

Discover the critical role of logistics nodes in the supply chain and their operational significance. ↩

Learn about the advantages of robotic systems in logistics and their impact on operational accuracy. ↩

Explore how AGVs enhance efficiency and safety in warehouse and port operations. ↩

Understand the role of redundancy in creating robust supply chains that can withstand disruptions. ↩