Shipping glacial acetic acid is risky. One small mistake can cause huge delays and fines. Here is a clear guide to help you ship it safely and compliantly.

To ship glacial acetic acid1 (UN 27892), you need end-to-end compliance. This means correctly identifying its hazards, using specialized packaging, choosing the right transport mode, and preparing precise customs documents. Every step is critical for a safe and timely delivery, especially to new markets.

I've seen many businesses struggle with this process. It seems complicated, but it's manageable if you break it down. Let's look at the details together. Understanding the risks and rewards is the first step to mastering this kind of shipment.

Why Is Shipping Acetic Acid Both High-Risk and High-Demand?

Acetic acid is needed everywhere for many industries. But its hazardous classification3 makes shipping a constant worry. Let's look at why demand is high and how to handle the risks.

Acetic acid is a key industrial chemical, driving high demand. Its UN number is UN 2789 Class 8 corrosive material4. This dual nature means its transport is highly regulated. You must balance the commercial opportunity with strict safety and compliance rules to succeed.

When I first started in this business, the dual nature of acetic acid was fascinating. On one hand, clients were constantly asking for it. On the other, the safety paperwork was immense. It's a classic case of high risk, high reward. To handle it, you need to understand both sides of the coin.

The Global Need for Acetic Acid

The demand is huge because this chemical is a building block for so many products we use every day. It's used to make vinyl acetate monomer, which goes into paints and adhesives. The textile industry uses it for dyeing processes. It's even used in producing pharmaceuticals and as a food additive (in a much-diluted form, of course). This widespread use means there's a constant, global need for reliable shipping. New markets are always opening up, especially in developing regions where industrial capacity is growing. For example, we've seen a surge in inquiries from manufacturing hubs in Africa recently.

Understanding the Inherent Risks

The high demand is matched by high risk. Glacial acetic acid is highly corrosive. It can cause severe skin burns and eye damage. It can also corrode metals, which presents a huge problem if the wrong packaging or transport unit is used. It also has a flammable vapor, adding a fire risk to the equation. Because of these dangers, international bodies have put strict rules in place. One mistake doesn't just mean a delayed shipment; it can lead to a serious safety incident.

| Demand Drivers | Risk Factors |

|---|---|

| Use in Paints & Adhesives | Class 8 Corrosive Material |

| Textile Industry Dyeing | Class 3 Flammable Subsidiary Risk |

| Pharmaceutical Production | Can damage containers and other cargo |

| Food & Beverage Industry | Health hazard to personnel if handled badly |

How Do You Classify Acetic Acid for International Shipping?

Incorrectly classifying hazardous materials is a big mistake. It can get your shipment rejected and cause legal problems. Let's get the classification for acetic acid right every time.

Glacial acetic acid is classified under UN 27892 as a Class 8 Corrosive substance. It may also have a Class 3 Flammable liquid subsidiary risk. You must use the correct Safety Data Sheet (SDS)5 to confirm its properties and ensure all documents match this classification.

I always tell my team that the Safety Data Sheet (SDS) is our bible for any hazardous shipment. It contains all the information we need, straight from the manufacturer. Before we even think about booking a container, we get the SDS and double-check every detail. It's a non-negotiable first step.

Breaking Down the Classification

International shipping regulations are built on a system of classifications. This ensures that everyone in the supply chain, from the warehouse worker to the ship's captain, knows exactly what they are handling and what precautions to take. For glacial acetic acid, the classification is very specific.

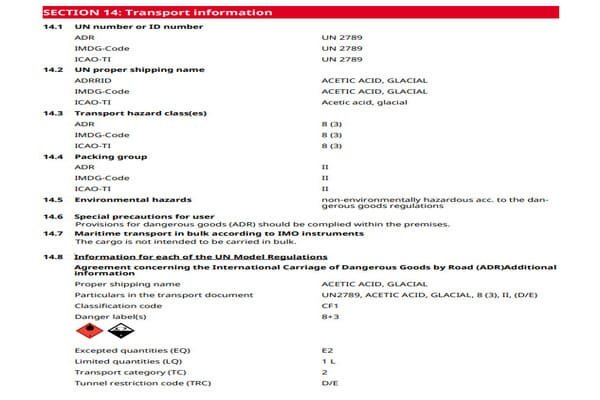

- UN Number: This is a four-digit number assigned by the United Nations to a specific hazardous substance. For acetic acid, it's UN 2789. This number must appear on all documents and package labels.

- Proper Shipping Name (PSN): This is the standard name used in all transport documents. It's "Acetic acid, glacial".

- Hazard Class: This defines the primary danger. For UN 2789, it is Class 8 (Corrosive substances).

- Subsidiary Risk: Some materials have more than one hazard. Acetic acid often has a Class 3 (Flammable liquids) subsidiary risk. The SDS will confirm if this applies to your specific product.

- Packing Group (PG): This indicates the degree of danger. Acetic acid is Packing Group II6, which means it presents a medium danger.

This information is the foundation for everything else. It determines the packaging you can use, the labels you must apply, and how the cargo must be stowed.

| Classification Element | Detail for Glacial Acetic Acid | Importance |

|---|---|---|

| UN Number | UN 2789 | Universal identifier for the substance. |

| Proper Shipping Name | Acetic acid, glacial | Standardized name for all documentation. |

| Primary Hazard Class | Class 8 (Corrosive) | Indicates the main danger is corrosion. |

| Subsidiary Hazard Class | Class 3 (Flammable) | Alerts to a secondary fire risk. |

| Packing Group | PG II | Defines the required strength of the packaging. |

What Kind of Packaging Is Required for Shipping Acetic Acid?

The wrong packaging for acetic acid is a disaster waiting to happen. Leaks can cause serious damage and endanger lives. Here are the specific, approved packaging types you must use.

You must use UN-approved packaging7 for acetic acid. This includes specialized drums or IBCs made from materials like stainless steel or specific plastics (e.g., HDPE) that resist corrosion. The packaging must be certified and marked with the correct UN specification codes.

We once had a shipment stopped at the port because the UN marking on the drums was slightly faded and hard to read. It was a tiny detail, but the port inspector was very strict. It cost the client a week in delays and extra inspection fees. That experience taught me that when it comes to hazardous goods, every single detail on the packaging matters.

Choosing the Right UN-Approved Packaging

You cannot just put acetic acid in any old drum. The packaging must be "UN-approved," which means it has undergone rigorous testing to prove it can safely contain the substance during transport. These tests simulate drops, stacking pressure, and leaks. Once a package design passes, it gets a UN specification marking stamped on it.

Material Compatibility is Key

Because acetic acid is highly corrosive, the material of the packaging is critical. It will eat through standard steel very quickly. Therefore, you must use containers made from materials that can resist it.

- High-Density Polyethylene (HDPE)8 Drums and IBCs: This is a very common choice. HDPE is a robust plastic that has excellent chemical resistance9 to acids.

- Stainless Steel Drums and IBCs: For higher purity requirements or specific client needs, stainless steel is a great option. It offers superior strength and resistance.

- ISO Tanks: For large, bulk shipments, an ISO tank is the most efficient method. These are specialized tank containers built with a stainless steel inner vessel and a protective frame.

The packaging must also be compatible with the Packing Group II danger level. This means it must meet a certain standard of strength and integrity.

How Do You Choose the Best Transport Mode for Acetic Acid?

Picking a transport mode seems simple, but it's not. For hazardous goods like acetic acid, the wrong choice can lead to a logistical mess. Let's break down the options.

Sea freight (ocean) is the most common method for bulk acetic acid, using ISO tanks10 or drummed containers. Air freight is faster but has stricter quantity limits. Regardless of the mode, you need proper DG declarations, placarding, and stowage plans to ensure compliance.

I worked with a client who needed to get a small, urgent shipment to a new factory in Africa. They initially wanted to use air freight for speed. However, the quantity limits for air transport meant we would have to send multiple small shipments, which was incredibly expensive. We ended up using a dedicated sea freight container on a faster vessel. It took a bit longer but saved them a huge amount of money and logistical headaches. It showed me that the "best" mode is always a balance of speed, cost, and compliance.

Comparing Your Transport Options

- Sea Freight (IMDG Code11): This is the workhorse for international chemical shipping. For acetic acid, you can ship it as a Full Container Load (FCL) with the product packed in drums or IBCs. For larger volumes, an ISO tank is much more efficient. Sea transport is cost-effective but slower. All handling must follow the International Maritime Dangerous Goods (IMDG) Code, which dictates stowage (e.g., away from foodstuffs) and segregation from other incompatible chemicals.

- Air Freight (IATA DGR12): This is the fastest option but also the most expensive and restrictive. The International Air Transport Association's Dangerous Goods Regulations (IATA DGR) are extremely strict. There are severe limits on the quantity of acetic acid you can ship per package on both passenger and cargo aircraft. This mode is usually reserved for small, time-sensitive samples or emergency supplies.

- Road/Rail (ADR/RID): For transport within continents like Europe, road (ADR) and rail (RID) regulations apply. These have their own specific rules for vehicle placarding, driver training, and routing.

Critical Operational Steps

Choosing the mode is just the beginning. The "end-to-end compliance control" I mentioned earlier is vital here. This includes:

- Correct Documentation: Preparing a flawless Shipper's Declaration for Dangerous Goods is essential. This document tells the carrier exactly what they are handling.

- Placarding and Marking: The container or vehicle must be marked with the correct placards (Class 8 and Class 3) on all four sides.

- Customs and Local Regulations: This is especially important for emerging markets. Some countries in Africa, for instance, have unique certification requirements or port policies. You must research these local rules beforehand to avoid having your cargo detained. We always work with a local agent to confirm these details before shipping.

Conclusion

Shipping glacial acetic acid requires careful, end-to-end control. By focusing on correct classification, packaging, and transport mode, you can navigate the complexities and deliver your cargo safely.

Understanding the risks associated with glacial acetic acid is crucial for safe shipping and compliance. ↩

Learn about the significance of UN 2789 for hazardous materials and its implications for shipping. ↩

Learn about the process of hazardous classification and its importance in shipping compliance. ↩

Explore the classification of corrosive materials and their shipping requirements for safety. ↩

Discover the critical role of the SDS in ensuring safe handling and shipping of hazardous materials. ↩

Discover the implications of Packing Group II for the handling and transport of hazardous substances. ↩

Find out why UN-approved packaging is essential for safely transporting hazardous substances. ↩

Learn about the advantages of HDPE in chemical packaging and its resistance to corrosive substances. ↩

Discover materials that provide chemical resistance for safe packaging of hazardous substances. ↩

Understand the use of ISO tanks for bulk shipments and their benefits in chemical transport. ↩

Explore the IMDG Code and its importance in the safe transport of hazardous materials by sea. ↩

Learn about IATA DGR and how it governs the air transport of dangerous goods. ↩